2021 Good Quality Implant Surgical Packs - Surgical Universal Pack – JPS Medical

2021 Good Quality Implant Surgical Packs - Surgical Universal Pack – JPS Medical Detail:

Features and benefits

Components & Details

Code:SUP001

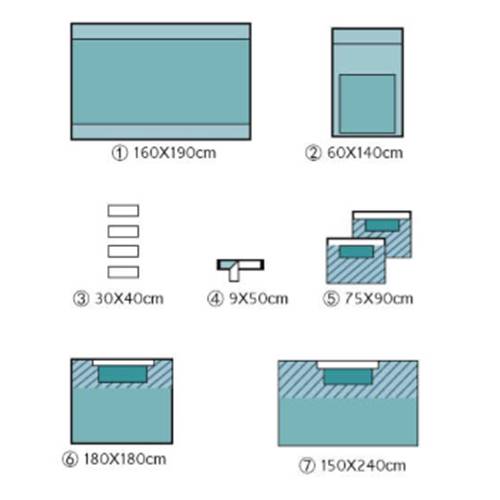

| NO. | Item | Quantity | |

| 1 | Back Table Cover 160x190cm | 1pc | 1 piece |

| 2 | Mayo stand cover 60*140cm | 1pc | 2 pieces |

| 3 | Hand Towel 30x40cm | 4pcs | 1 piece |

| 4 | OP tape 9*50cm | 1pc | 1 piece |

| 5 | Adhesive side drape 75*90cm | 2pcs | 1 piece |

| 6 | Adhesive bottom drape 180*180cm | 1pc | 1 piece |

| 7 | Adhesive top drape 150*240cm | 1pc | 4 pieces |

What are the benefits for disposable surgical Universal packs?

The first is safety and sterilization. The sterilization of the disposable surgical universal pack is no longer left up to the doctors or the medical staff but rather is not needed as the surgical pack is one time use and is disposed of afterwards. This means that as long as the disposable surgical pack is used once, there is no chance of cross contamination or of spreading any diseases with the use of the disposable pack. There is no need to keep these disposable packs around after use in order to sterilize them.

Another benefit is that these disposable surgical packs are less expensive than traditional reused surgical pack. This means that more attention can be paid to things like taking care of patients rather than keeping up with expensive reusable surgical packs. Since they are less expensive they are also not as big of a loss if they are broken or lost before they are used.

Product detail pictures:

Related Product Guide:

Core elements of compost maturity 2021 Good Quality Implant Surgical Packs - Surgical Universal Pack – JPS Medical , The product will supply to all over the world, such as: Slovakia, UK, Portugal, Dry granulation equipment is a high-efficiency mixing and granulating machine. By mixing and granulating materials of different viscosities in one equipment, it can produce granules that meet the requirements and achieve storage and transportation. particle strength

It's really lucky to find such a professional and responsible manufacturer, the product quality is good and delivery is timely, very nice.