China wholesale Procedure Surgical Pack - Surgical Angiography Pack – JPS Medical

China wholesale Procedure Surgical Pack - Surgical Angiography Pack – JPS Medical Detail:

Features and benefits

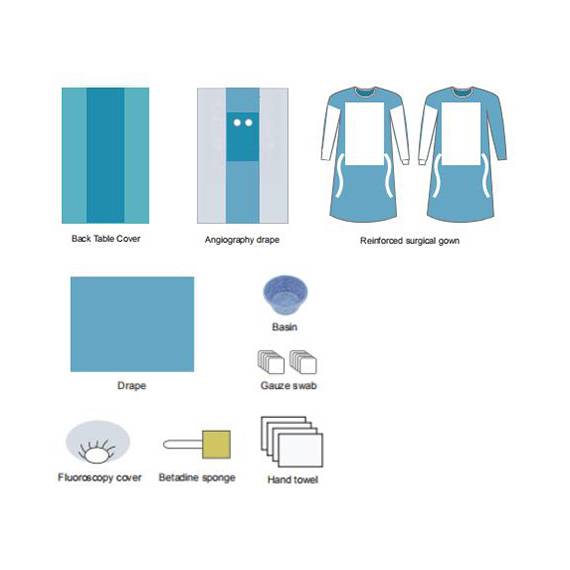

Components & Details

Code:SAP001

| NO. | Item | Quantity |

| 1 | Back Table Cover 160x190cm | 1 pc |

| 2 | Fluoroscopy cover | 1 pc |

| 3 | Basin 500cc | 1 pc |

| 4 | Gauze swab | 10 pcs |

| 5 | Hand towel 30x40cm | 4 pcs |

| 6 | Reinforced surgical gown | 2 pcs |

| 7 | Betadine sponge | 1pc |

| 8 | drape 100*100cm | 1pc |

| 9 | Angiography drape | 1pc |

What are the benefits for disposable surgical packs?

The first is safety and sterilization. The sterilization of the disposable surgical angiography pack is no longer left up to the doctors or the medical staff but rather is not needed as the surgical pack is one time use and is disposed of afterwards. This means that as long as the disposable surgical pack is used once, there is no chance of cross contamination or of spreading any diseases with the use of the disposable pack. There is no need to keep these disposable packs around after use in order to sterilize them.

Another benefit is that these disposable surgical packs are less expensive than traditional reused surgical pack. This means that more attention can be paid to things like taking care of patients rather than keeping up with expensive reusable surgical packs. Since they are less expensive they are also not as big of a loss if they are broken or lost before they are used.

On top of all that, disposable surgical packs, when properly dealt with, are safer for the environment. Proper disposal keeps syringes out of common reach and helps to keep our communities safe.

Product detail pictures:

Related Product Guide:

Ventilation and Oxygen Supply - Manure composting is an important factor in the lack of air and oxygen. China wholesale Procedure Surgical Pack - Surgical Angiography Pack – JPS Medical , The product will supply to all over the world, such as: Moldova, Italy, Tunisia, Fertilizer granulating machine

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.