Disposable Plastic Apron - China Factory, Suppliers, Manufacturers

Promoting Fermentation and Decomposition by Turning Machine Disposable Plastic Apron, Chemical Integrator , Face Shields , Indicator Strips ,Autoclave Tape Colour Change . Organic fertilizer fermentation equipment is used for the industrialized fermentation treatment of organic solids such as animal manure, domestic waste, sludge, crop straw, etc. Generally, there are chain plate turners, walking turners, double helix turners, and trough turners. Different fermentation equipment such as machine, trough hydraulic turner, crawler type turner, horizontal fermentation tank, roulette turner, forklift turner and so on. The product will supply to all over the world, such as Europe, America, Australia,Somalia, Birmingham,Lahore, Rio de Janeiro.Organic Fertilizer Machinery

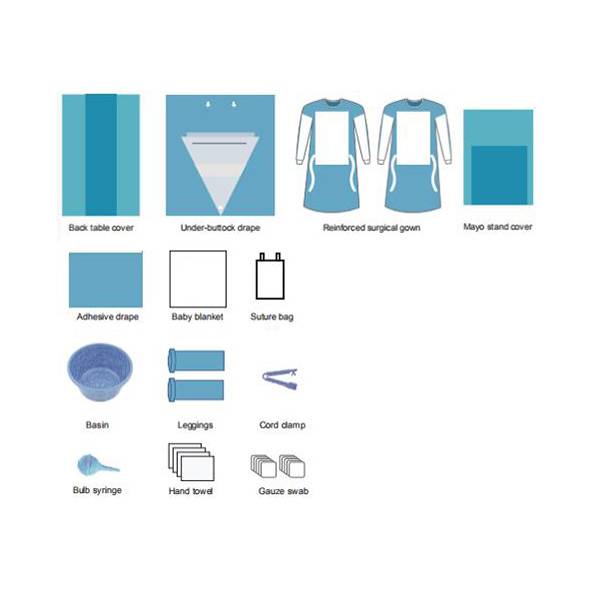

Related Products